Road construction is a complex process that requires the use of various specialized equipment. Among these, road planers play a crucial role in preparing road surfaces for new pavement. In this comprehensive guide, we will delve into the functions, benefits, and applications of road planers, shedding light on their significance as essential equipment for efficient and effective road construction projects.

What are Road Planers?

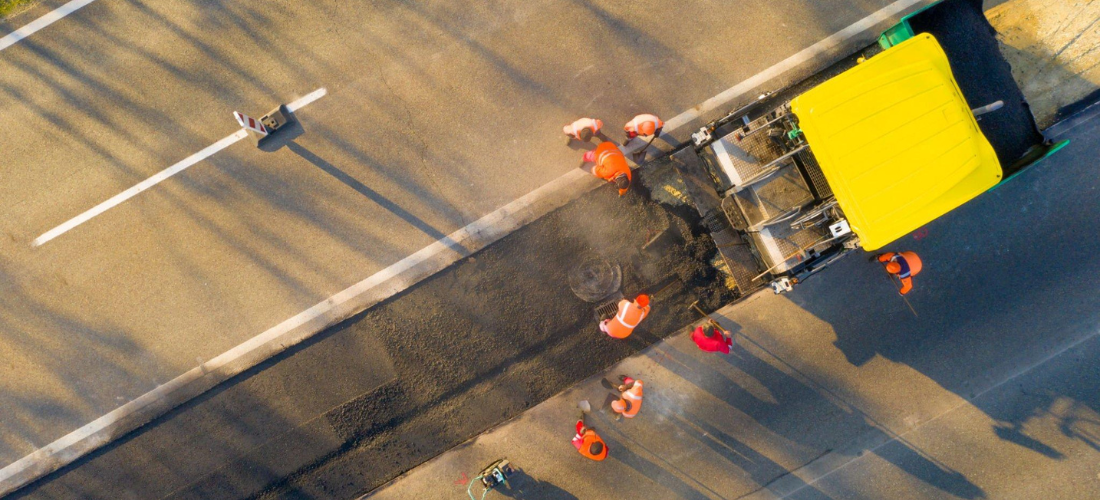

Road planers, also known as cold milling machines or asphalt milling machines, are heavy-duty equipment used in road construction. These machines are designed to remove existing pavement layers to create a smooth and even surface. Road planers are equipped with rotating cutting drums with multiple cutting tools that remove the asphalt or concrete surface, allowing for subsequent treatments or the application of new pavement.

Functions of Road Planers:

The primary function of road planers is to remove the top layer of existing pavement to the desired depth. This process helps eliminate irregularities, cracks, and other imperfections in the road surface. Additionally, road planers can be used to correct road profiles, remove road markings, and create rumble strips or other road features.

Benefits of Road Planers:

Road planers offer several benefits in road construction projects. Firstly, they provide a cost-effective solution for pavement removal compared to traditional methods. By selectively removing the damaged or deteriorated layers, road planers minimize the amount of material that needs to be hauled away and disposed of. This results in cost savings and reduces the environmental impact of the construction process.

Furthermore, road planers improve the road’s structural integrity by creating a smooth and even surface. This facilitates better adhesion of new pavement materials, ensuring a longer-lasting and more durable road surface. Road planers also improve ride quality and enhance safety by eliminating bumps, unevenness, and other hazards on the road.

Applications of Road Planers:

Road planers find applications in various road construction projects. They are commonly used for road resurfacing, where the top layer of existing pavement is removed to make way for a new layer of asphalt or concrete. Road planers are also used in rehabilitation projects to remove damaged or deteriorated pavement layers before applying new treatments or overlays.

Additionally, road planers are utilized in the construction of new roads to prepare the sub-base or base layers. They can be used to create trenches or grooves for utility installations, such as drainage systems or underground cables. Road planers are versatile machines that adapt to different project requirements, making them indispensable in road construction.

Expertise and Precision:

Operating road planers requires expertise and precision. Skilled operators are trained to adjust the cutting depth, cutting speed, and other parameters to ensure accurate and efficient pavement removal. Their expertise ensures that road planers are utilized effectively, achieving the desired results while minimizing disruptions and maintaining safety on the construction site.

Conclusion:

Road planers are essential equipment for efficient and effective road construction projects. Their functions, benefits, and applications make them indispensable in the industry. Road planers provide a cost-effective solution for pavement removal, improve the road’s structural integrity, and enhance ride quality and safety. With skilled operators at the helm, road planers play a crucial role in preparing road surfaces for new pavement and contribute to the development of safe and durable road infrastructure.